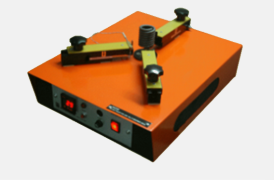

The UNIQUE SPIRAL HEATER is supplied with heating coils of 1 KW and 75 KW. 1 KW coil is used for heating bearing of bore size 55 mm to 100 mm. The 1 75 KW coil is used for heating the bearings of bore size 100 to 150 mm .. The heating coils can be easily changed since they are just of plug in type. The unit ensures uniform heating through the centering support The temperature control sensor is in contact with the inner ring of the bearing. Once the set temperature is reached the same can be seen on the display panel and one can hear the audio alarm signaling the job has been heated. The unit is provided with a micro switch which switches off the current once the job is heated to the set temperature. This is an additional safety feature provided. Apart form bearing couplings, cams rings etc. can also be heated to an accuracy of +I- 2 deg C