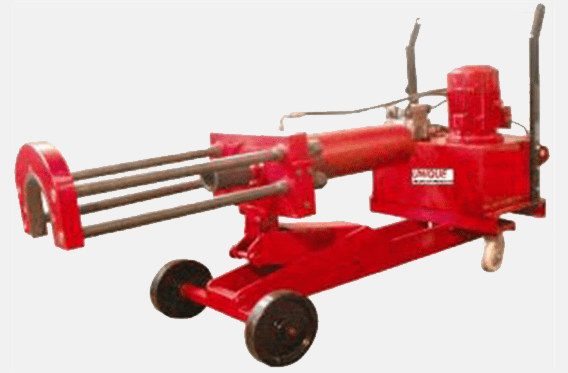

Pulling and installing Cartridge Rollers have become easier than ever with our spectacular range of CTRB Puller Cum Installer. The technical specifications will enumerate why the equipment is perfect for extensive operations:

- Bearing installation capacity ranges from 70 ton

- The dismounting is of 100 tons

- Hydraulic pressure 500 bars

- Oil reservoir capacity is of 40 liters on an approximation

The CTRB Puller Cum Installer is one of the top-of-the-line instruments we have. If you wish to experience advanced operations, get it right now.

Electric Hydraulic Rail Road Axle Journal Cartridge Tapered Roller Bearing Puller / Installer with Hydraulic Power Pack Unit are suitable for removing and installing Cartridge tapered roller bearing from axle.

Technical Specification:

- Stroke Horizontal : 400 mm ( approx )

- Capacity:

- For Bearing Installation (mounting) : Min. 70 Tons

- For Bearing dismounting : Min. 100 Tons

- Speed:

- Speed of advancement of ram in idle condition : 28.3 cm/min (approx) i.e., without load

- Speed of dismounting the bearing : 7.4 cm/min (approx)

- Speed of mounting the bearing : 10.5 cm/min (approx)

- Type of Cylinder: Single Hydraulic Double Acting Cylinder

- Hydraulic Pressure: 500 Bars (Max.)

- Other Power pack details

- Suction & return line filter

- Oil reservoir capacity: 40 Litres ( approx )

- Control Valve

- Direction Valve: Three position four-way hand-operated open centre valve.

- Other control valves :

- Direction Valve: Three position four-way hand-operated open centre valve.

- Other control valves :

- Built in pressure relief valve for safety maximum pressure 500 Bars

- Field adjustable pressure relief valve maximum pressure 500 Bars

- Motor details :

- Horse Power – 5 HP (or suitable) capacity with Motor Starter and Motor Protection Circuit Barker ( MPCB )

- Phase – Three Phase

- Voltage – 415 Volts ± 10%, 50 Hz.

- Height from floor to center of installation table from 400 mm minimum to 600 mm Maximum: Hydraulic height adjustment arrangement is provided.

- Extractor / puller and power pack: Mounted on trolley.

- The trolley is mounted on wheels to make it mobile and is easily maneuverable.

- All parts with critical application, such as pulling shoe, inserts, adapters is made of alloy steel to ensure long life and minimum wear.

- The equipment is of such design which will enable in faster and simpler way of pulling / installing operations.

- The use of puller / installer will consume an absolute minimum time and effort.

- The machine is capable of giving the out turn of minimum 30 wheel sets for mounting / dismounting, during a shift of 08 hours under ideal condition.

- We will supply the accessories like complete set of pulling and pushing adaptors, guide tub, yoke plates, etc if needed extra.

- Hydraulic and electric components used is of standard and quality makes. Machine is supplied with necessary hydraulic oil fill and 5 M electric supply lead with plug and socket.

- The equipment is completely portable for easy and convenience positioning out of the way storage and can be conveniently operated by one operator

- The construction of equipment is designed to enable faster and simpler way of pulling / installing operations by two operators